Good Price Lead-Free PVC Foam sheets

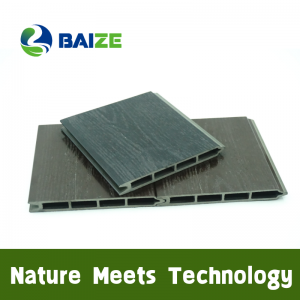

Baize PVC foam boards are made primarily of PVC resin, a thermoplastic polymer synthesized from the polymerization of vinyl chloride monomers. The manufacturing process involves blending the PVC resin with foaming agents, stabilizers, fillers, and other additives to create a homogenous mixture. This mixture is then heated and extruded or molded into the desired shape, resulting in a foam board with a cellular structure that provides its distinct properties.

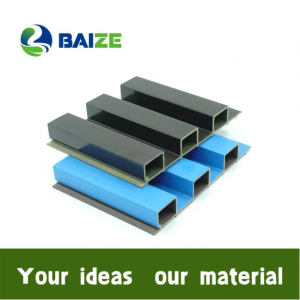

Properties of PVC Foam Boards

Lightweight: Due to their cellular structure, PVC foam boards have a low density, making them lightweight and easy to handle.

Water Resistance: PVC foam boards are non-absorbent and resist water damage, making them ideal for use in wet environments or applications where moisture is a concern.

Chemical Resistance: These boards are resistant to most chemicals, solvents, and acids, making them suitable for use in laboratories, chemical plants, or other corrosive environments.

Insulation: PVC foam boards have excellent thermal and acoustic insulation properties due to their closed-cell structure, reducing energy consumption and noise transmission.

Dimensional Stability: They maintain their shape and size under various environmental conditions, including changes in temperature and humidity.

Workability: PVC foam boards are easy to cut, shape, and bond with various adhesives, making them a favorite among architects, designers, and fabricators.

Applications of PVC Foam Boards

Construction: PVC foam boards are used in building applications like wall cladding, insulation, and decorative paneling due to their lightweight, water-resistant, and insulating properties.

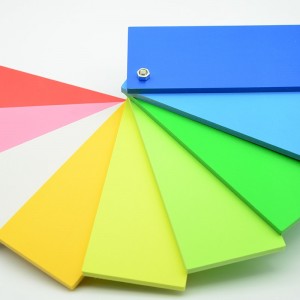

Signage and Advertising: These boards are ideal for outdoor signs, exhibition displays, and point-of-purchase displays because of their durability, weather resistance, and ease of printing.

Interior Design: They are used for creating furniture, cabinetry, and partitions due to their excellent workability and aesthetically pleasing appearance.

Marine Industry: PVC foam boards are used for boat interiors, cabinets, and seating because of their water resistance, lightweight nature, and resistance to rotting.

Industrial Applications: These boards are used for chemical tanks, laboratory equipment, and clean room construction due to their chemical resistance and low moisture absorption.

In conclusion, PVC foam boards are a versatile and cost-effective material with a wide range of applications in various industries. Their unique combination of lightweight, water resistance, insulation, and workability make them a popular choice for both functional and decorative purposes.